SHARP TOP ROLLER CHAIN

The formula for successfully running a sawmill/ lumber mill is simple. Run at the highest speed possible with the smallest margin of error, waste, and downtime. As a world-class supplier of premium quality industrial components and knowledge, we like to play our part in your success by setting the bar of expectations when it comes to a high-quality product and industry-leading customer service. Our sharp top roller chains are one of the many products that we are confident will not disappoint, and have become one of the widest used chains in forestry and lumber applications. It utilizes a uniquely engineered design that allows the chain to physically grip onto the lumber or product to pull it along as a conveyor. Because of the application types that sharp top chains are used in our chains have been manufactured to the utmost premium stands while remaining competitively priced without corner cutting. Using a low-quality chain has proven negative side effects on sprockets, productivity, and other components in your conveyor system thus affecting your bottom line! These sharp top chains are manufactured to meet and exceed the American National Standards Institute (ANSI) B29.1 for American chain sizes, and ISO Metric British Standards for metric sharp top chains. At USA Roller Chain and Sprockets we are proud to offer a chain with industry-leading technologies implemented, cold forged solid components, and the most requested designs in the industry.

SHARP TOP CHAIN FEATURES

- High-precision teeth for optimal grip and least amount of penetration

- Heat treated shot peened pins, bushings, rollers, and side plates for optimal fatigue strength and working life

- Low draft tooth profile that distributes weight and reduces losses from bruising

- Triple alloy steel rivet pins and optimal riveting for extended life

- Ballized bushed plates for uniform hole size

- Pre-lubed with a premium lubricant designed for sharp top chain

- Unique solid center plate design that all but eliminates breakage from sawdust packing

- Chrome Pins (standard in some sizes)

- Machined Smooth Bottoms to reduce damage to the chain beds

- Anti-Corrosive Coatings

- Induction Hardened Teeth

SHARP TOP ROLLER CHAIN STYLES

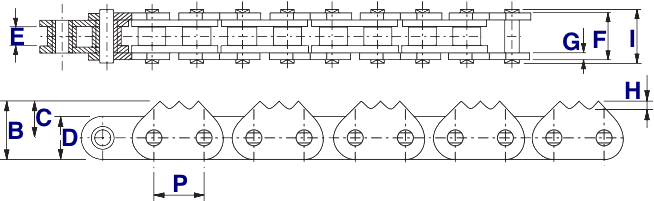

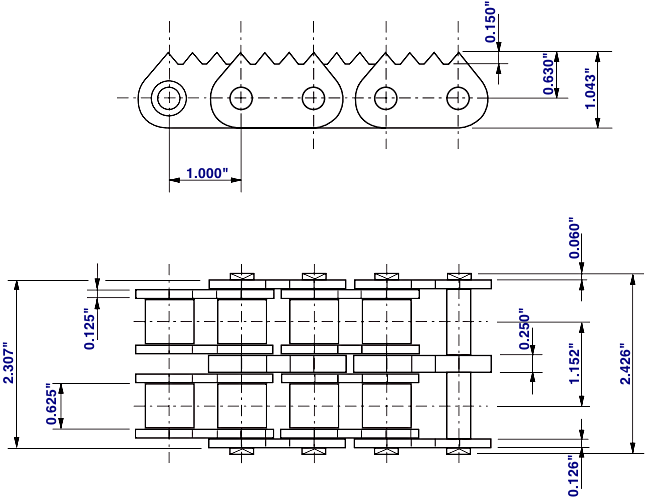

3-POINTS EVERY 2-PITCHES SHARP TOP CHAIN

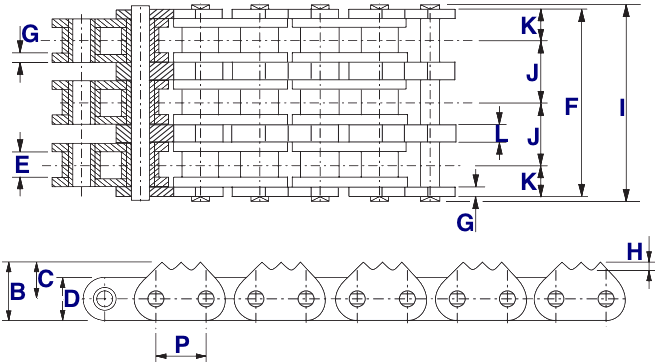

| (P) | (B) | (C) | (D) | (E) | (F) | (G) | (H) | (I) | |

|---|---|---|---|---|---|---|---|---|---|

| 60-1 | 0.750″ | 0.850″ | 0.512″ | 0.689″ | 0.500″ | 0.878″ | 0.094″ | 0.094″ | 1.000″ |

| 80-1 | 1.000″ | 1.140″ | 0.685″ | 0.914″ | 0.622″ | 1.130″ | 0.125″ | 0.125″ | 1.275″ |

| 100-1 | 1.250″ | 1.325″ | 0.750″ | 1.142″ | 0.711″ | 1.374″ | 0.156″ | 0.125″ | 1.544″ |

| 120-1 | 1.500″ | 1.594″ | 0.909″ | 1.370″ | 1.000″ | 1.750″ | 0.187″ | 0.125″ | 1.942″ |

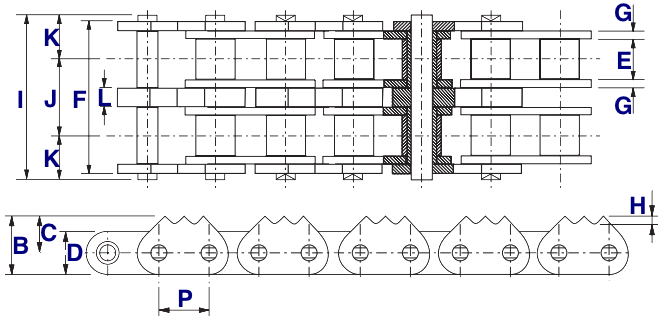

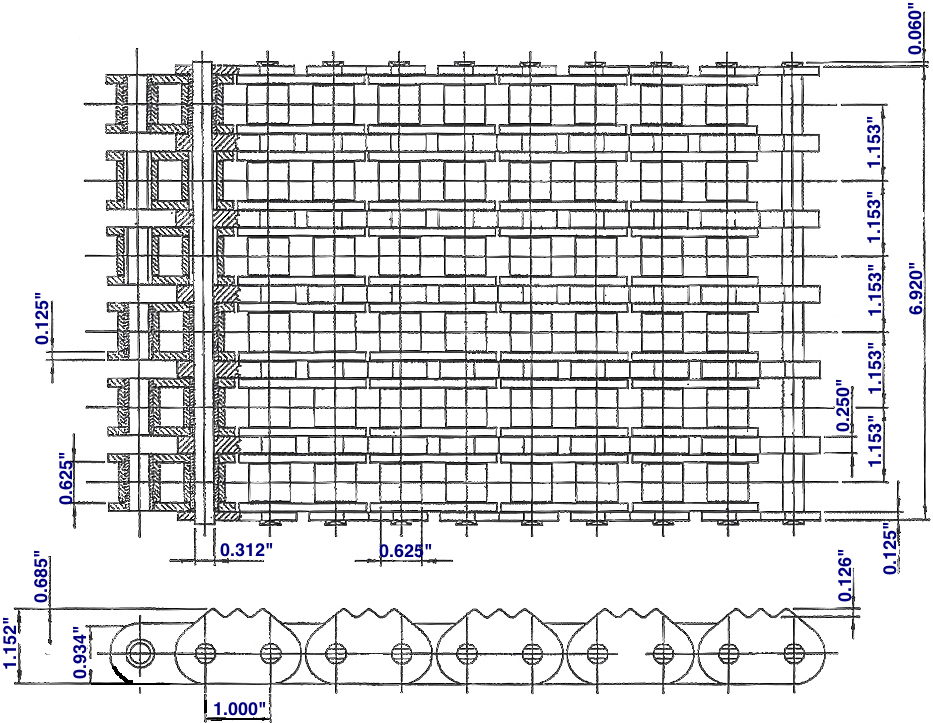

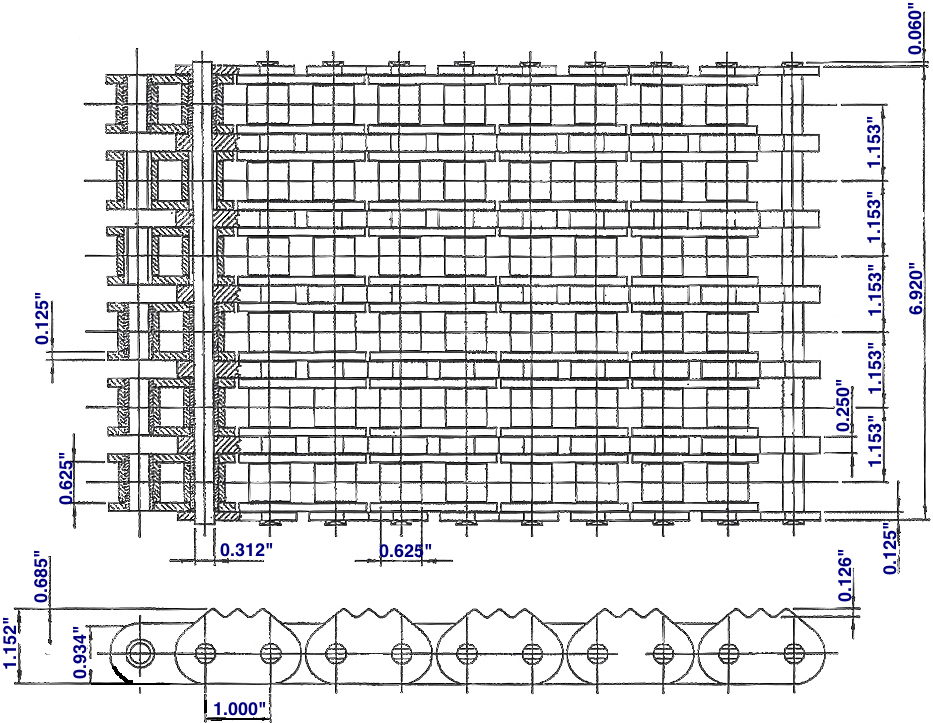

| (P) | (B) | (C) | (D) | (E) | (F) | (G) | (H) | (I) | (J) | (K) | (L) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 60-2 | 0.750″ | 0.854″ | 0.510″ | 0.685″ | 0.500″ | 1.774″ | 0.094″ | 0.094″ | 1.900″ | 0.898″ | 0.500″ | — |

| 80-2 | 1.000″ | 1.140″ | 0.685″ | 0.914″ | 0.625″ | 2.310″ | 0.125″ | 0.125″ | 2.420″ | 1.153″ | 0.630″ | 0.249″ |

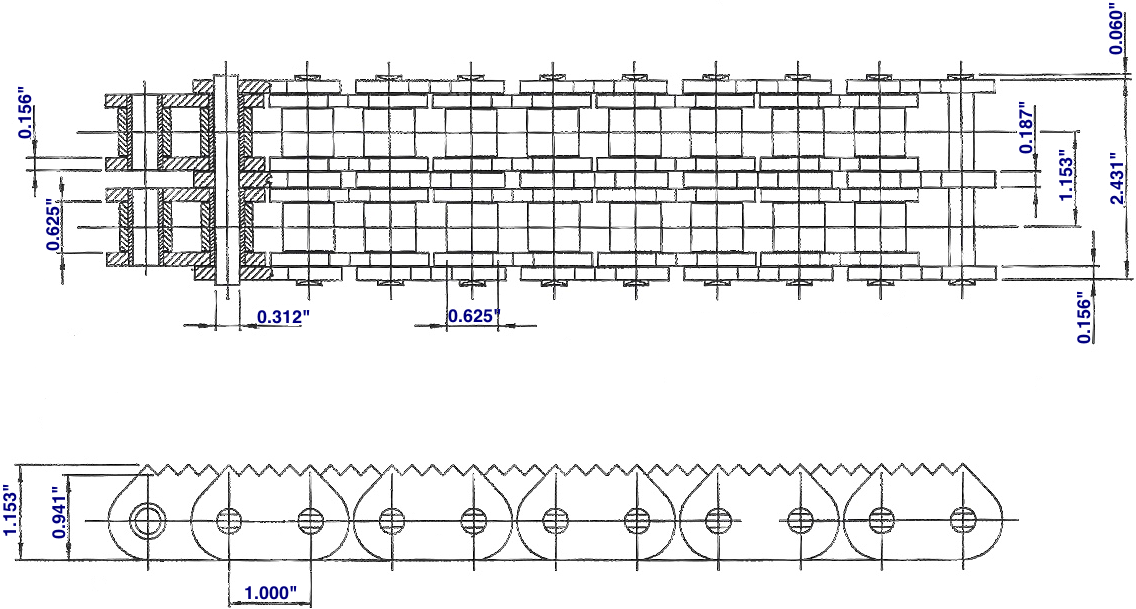

| 80H-2 | 1.000″ | 1.152″ | 0.685″ | 0.934″ | 0.625″ | 2.431″ | 0.156″ | 0.126″ | — | 1.153″ | — | 0.312″ |

| 100-2 | 1.250″ | 1.325″ | 0.715″ | 1.147″ | 0.750″ | 2.805″ | 0.156″ | 0.125″ | 2.953″ | 1.409″ | 0.772″ | 0.310″ |

| 120-2 | 1.500″ | 1.594″ | 0.909″ | 1.370″ | 1.000″ | 3.300″ | 0.187″ | 0.125″ | 3.729″ | 1.787″ | 0.970″ | 0.410″ |

Triple Strand:

| (P) | (B) | (C) | (D) | (E) | (F) | (G) | (H) | (I) | (J) | (K) | (L) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 60-3 | 0.750″ | — | 0.500″ | 0.685″ | 0.500″ | — | 0.094″ | — | 2.792″ | 0.897″ | — | 0.181″ |

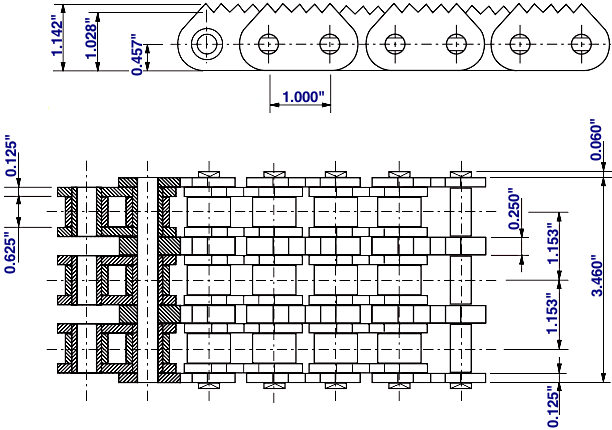

| 80-3 | 1.000″ | 1.140″ | 0.685″ | 0.914″ | 0.625″ | 3.460″ | 0.125″ | 0.126″ | 3.580″ | 1.153″ | 0.650″ | 0.250″ |

| 100-3 | 1.250″ | 1.325″ | 0.754″ | 1.147″ | 0.750″ | 4.200″ | 0.156″ | 0.126″ | 4.362″ | 1.409″ | 0.772″ | 0.310″ |

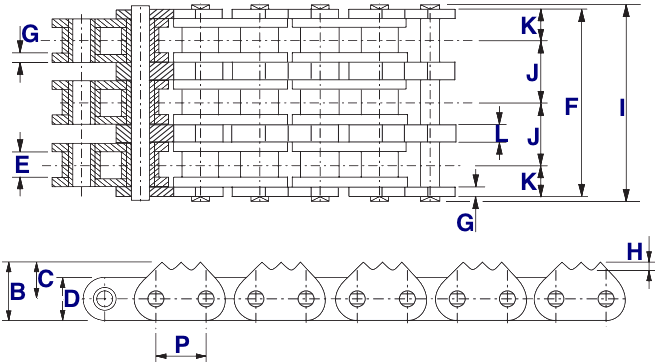

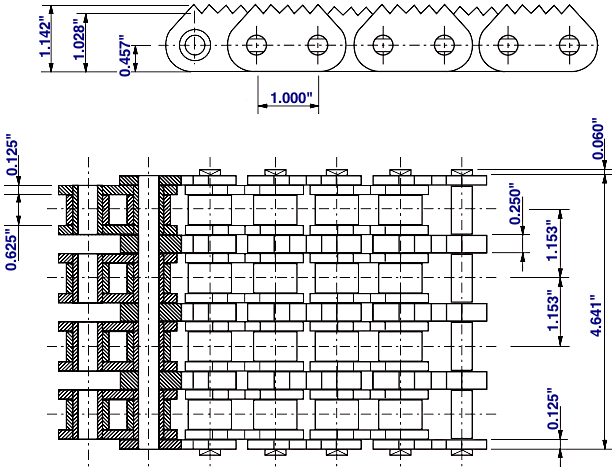

Quad Strand:

| (P) | (B) | (C) | (D) | (E) | (F) | (G) | (H) | (I) | (J) | (K) | (L) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 80-4 | 1.000″ | 1.140″ | 0.685″ | 0.914″ | 0.625″ | 4.614″ | 0.125″ | 0.126″ | 4.740″ | 1.153″ | 0.645″ | 0.250″ |

| 120-4 | 1.500″ | 1.594″ | 0.909″ | 1.370″ | 1.000″ | 7.150″ | 0.187″ | 0.125″ | 7.303″ | 1.787″ | 0.970″ | 0.410″ |

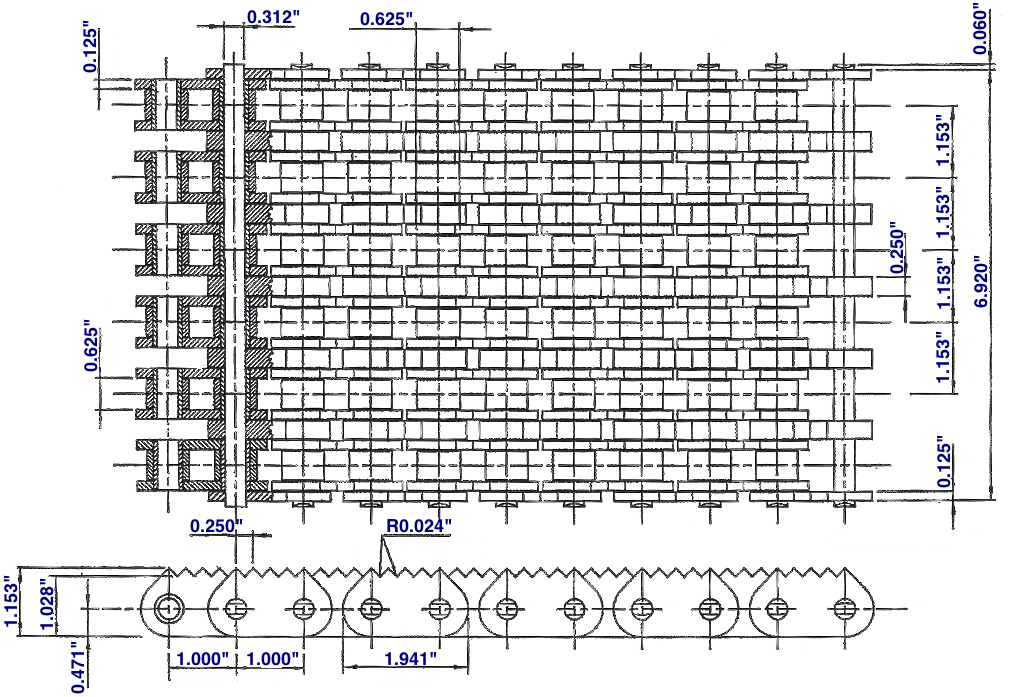

80-6 With 3 Points Every 2nd Pitch:

80-8 With 3 Points Every 2nd Pitch:

4-POINTS EVERY PITCH SHARP TOP CHAIN

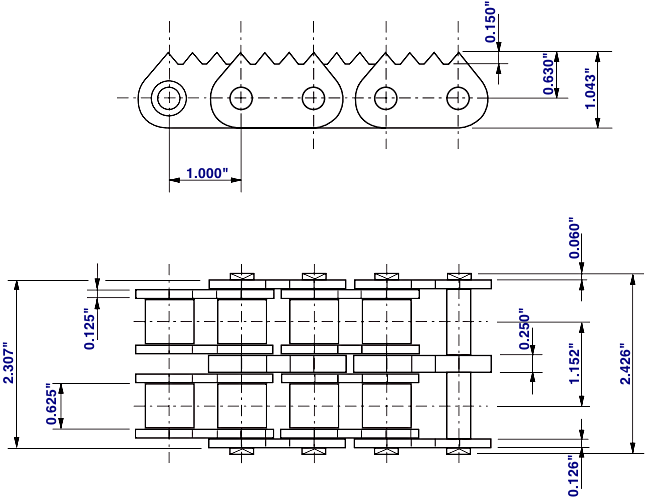

80-2 With 4 Points Every Pitch:

| (P) | (B) | (D) | (E) | (F) | (I) | (J) | (K) | |

|---|---|---|---|---|---|---|---|---|

| 16B-1 | 25.40mm | 26.50mm | 21.10mm | 17.00mm | 33.50mm | 38.89mm | — | 17.00mm |

| 16B-2 | 25.40mm | 26.50mm | 21.10mm | 17.00mm | 67.99mm | 73.41mm | 31.88mm | 17.00mm |

| 16B-3 | 25.40mm | 26.50mm | 21.10mm | 17.00mm | 99.89mm | 105.30mm | 31.88mm | 17.00mm |

| 20B-1 | 31.80mm | 32.80mm | 26.42mm | 19.60mm | 43.21mm | 49.30mm | — | |

| 20B-2 | 31.80mm | 32.80mm | 26.42mm | 19.60mm | 79.71mm | 85.00mm | 36.45mm | 19.60mm |

| 20B-3 | 31.80mm | 32.80mm | 26.42mm | 19.60mm | 116.10mm | 122.20mm | 36.45mm | 19.60mm |

| 24B-1 | 38.10mm | 38.50mm | 33.40mm | 25.40mm | 53.39mm | 59.90mm | — | 25.40mm |

| 24B-2 | 38.10mm | 38.50mm | 33.40mm | 25.40mm | 101.80mm | 108.40mm | 48.360 | 25.40mm |

| 24B-3 | 38.10mm | 38.50mm | 33.40mm | 25.40mm | 150.20mm | 156.80mm | 48.360 | 25.40mm |

| 32B-1 | 50.80mm | — | 48.26mm | 30.99mm | 75.40mm | 64.70mm | — | 38.10mm |

| 32B-2 | 50.80mm | — | 48.26mm | 30.99mm | 133.90mm | 126.00mm | 58.550 | 38.10mm |

5-POINTS EVERY PITCH SHARP TOP CHAIN

80-2 With 5 Points:

80H-2 With 5 Points:

80-3 With 5 Points:

80-4 With 5 Points:

80-6 With 5 Points: